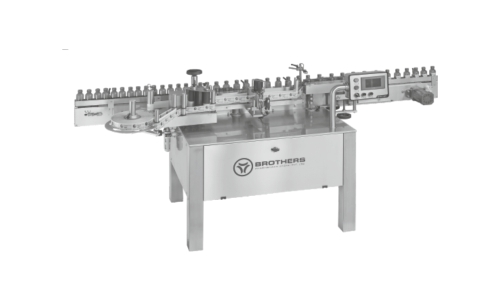

LABELSTIK-150B

The Automatic Vertical Sticker Labelling Machine Model

LABELSTIK-150B, is one of the most user friendly Label

Dispenser Machine. The Machine incorporates latest

sophisticated Micro Processor Control Label Dispensing system with user

friendly Sensing system for Label and Product. The Machine is suitable

for

Labelling on Round Bottle, Jars and other round objects. It is capable

of Labelling up to 150 Products per minute depending on products

diameter and

label size.

Machine is suited for Glass, Plastic Aluminium, PET bottles of

Pharmaceuticals, Mineral Water, Food Products and Pesticides having

bigger Label

Height and Length.

The Machine's Positive Drive Spacing Roller

eliminates the need of Feed Worm or Star Wheel for uniform product

separation, for regular shaped

containers. Smart Vertically / Horizontally Adjustable Pressing Device

of the machine makes the alignments for the Height and Diameter of

Containers

easy and convenient.

The Sticker Labelling Machine

LABELSTIK-150B has its own unique single point synchronised speed

control system. The Inbuilt Automated Label

Length detection systems eliminates any need for manually feeding and

storing of Label Length data in memory and retrieving the same every

time for

change of Label Size & re-starting the machine. The System thus

saves valuable time, avoiding machine-down time, and helps achieve

higher

production.

Machine can be supplied with Optional Toughened

(Tampered) Glass or Acrylic Safety Cabinet. Machines having required all

basic features as a

standard fitment to match the current market needs and also saves cost

and time.

Technical Specifications

| Label Height | 8 mm to 90/120/150 mm Standard* |

| Label Length | 12 mm Minimum |

| Label Roll Dia. | 400 mm |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | appx. 3 mm |

| Product Diameter | 15 mm to 90 mm* |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 1.5 Amp. |

| Capacity | 0.75 Kw |

| Speed | Up to 150 Labels per minute depending on Product and Label Size |

| Conveyor height | 830-875 mm* |

| Overall dimension | 2440 mm(L) X 940 mm(W) X 1300 mm (H) |

| With T.G. Cabinet | 2440 mm(L) X 940 mm(W) X 1900 mm (H) |

| Machine Direction of Movement | Left to Right from operator side |

| * Specification can be changed as per customers requirements | |

×

×